Description

| Product supplied | City |

| Plate Flanges for Automobile Industry | Delhi, New Delhi |

| Plate Flanges supply | Hyderabad, Telangana |

| Plate Flanges supply for Water Supply System | Banglore, Karnataka |

| Plate Flanges for Chemical industry | Surat, Gujarat |

Cities We Supply Weld Flanges

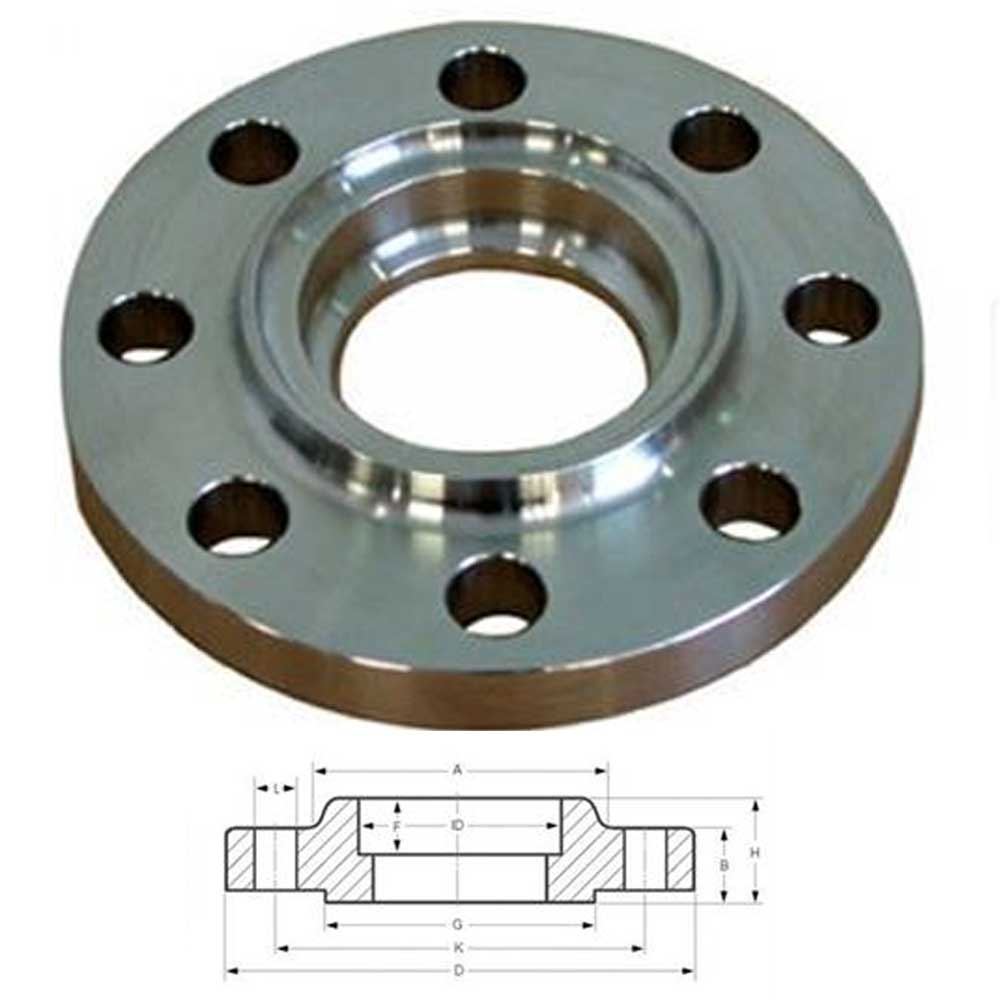

Hilton Metal Industries stands at the forefront as a premier stockist and dealer of high-quality hub flanges in India, offering an extensive selection designed for a wide range of commercial and industrial applications. Our hub flanges ensure reliable and secure connections between various engine components. As a trusted hub flanges stockist, we maintain a substantial inventory in diverse sizes, shapes, and materials, allowing us to efficiently meet the varied needs of our clients with speed and precision.

| City we supply Weld Flanges: | |||||

|---|---|---|---|---|---|

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Sri City | Bareilly | Hosdurg | Pithampur |

Why Choose Hilton Metal Industries?

With a commitment to delivering excellence, Hilton Metal Industries stands out as a trusted supplier of blind flanges. We prioritize quality, precision, and customer satisfaction, ensuring that our products meet the highest industry standards. Our experienced team is dedicated to providing expert guidance and support, helping clients select the best solutions for their specific needs.

Choose Hilton Metal Industries for Reliable Weld Flanges

Experience the quality and reliability of Hilton Metal Industries’ blind flanges, engineered to support your critical operations. With our emphasis on precision and performance, we deliver solutions you can trust for long-lasting and efficient service.

| Countries we export Weld Flanges: | ||||

|---|---|---|---|---|

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | New Zealand |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | Germany |

| France | Italy | South Korea | Poland | Belgium |