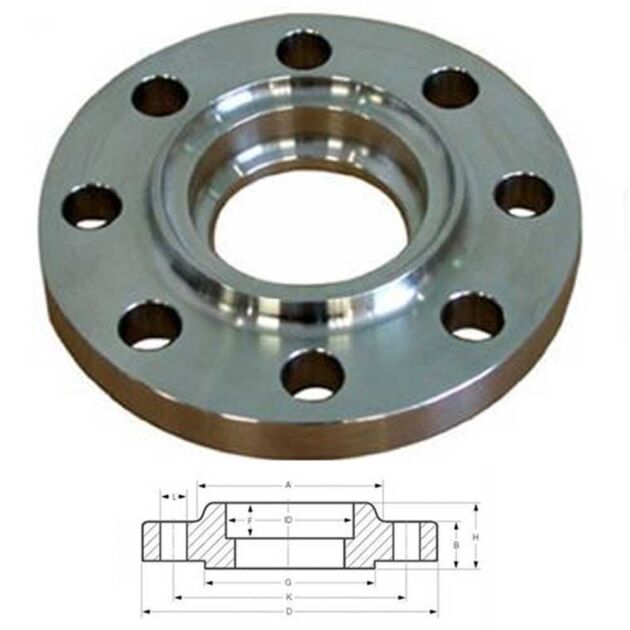

About Ring Joint Flanges

Ring Joint Flanges (RTJ) are designed for use in high-temperature and high-pressure environments, typically exceeding 800°F (427°C) and/or Class 600 pressure ratings. These flanges feature grooves cut into their faces to accommodate steel ring gaskets, which are compressed between the flanges when tightened. The compression of the gasket into the grooves creates a metal-to-metal seal, ensuring a reliable and durable connection.

While some Ring Joint Flanges may include a raised face with a ring groove machined into it, the raised face does not contribute to the sealing mechanism. In RTJ applications, the primary sealing action is achieved through the contact of the compressed gasket with the flange grooves, rather than the raised faces of the flanges. This ensures that the gasket is not further deformed or crushed, maintaining the integrity of the seal and preventing leakage due to external factors like vibration and bolt tension.

About Ring Type Joint Gaskets

Ring Type Joint (RTJ) gaskets are metallic sealing rings engineered for high-temperature and high-pressure applications. These gaskets are used in conjunction with specially designed flanges to provide reliable, leak-proof seals when installed properly.

RTJ gaskets seal by creating “initial line contact” or a wedging action between the gasket and the flange. As bolts are tightened, pressure is applied to the seal interface, causing the “softer” metal of the gasket to flow into the finer structure of the harder flange materials, thereby forming a tight, efficient seal.

The Style R ring is the most commonly used RTJ gasket, manufactured in accordance with ASME B16.20 for use with ASME B16.5 flanges, ranging from class 150 to class 2500. The Style R ring comes in octagonal and oval configurations, with the oval offering a slightly lower sealing efficiency than the octagonal ring. The oval cross-section is often used in older round bottom grooves, while newer flat bottom grooves can accept either oval or octagonal cross-sections.

RTJ gaskets are designed to handle high-pressure applications, with Style R capable of sealing pressures up to 6,250 psi, and RX type and BX type gaskets designed for even higher pressures. RX gaskets can seal pressures up to 700 bar, while BX gaskets are ideal for extreme pressures up to 1500 bar and are specifically suited for API BX-type flanges.

To ensure proper sealing, the sealing surfaces of RTJ flanges and grooves must be finely finished to 63 microinches and free of imperfections. The gasket’s hardness is lower than that of the flanges to facilitate the initial line contact and ensure a reliable seal.

Ring Joint Flanges Applications and Uses

- Homes and Buildings: Used in plumbing and HVAC systems for reliable pipe connections.

- Transporting Materials: Essential for pipelines and connections in material transportation industries.

- Automotive Industry: Common in engine and exhaust systems where high-pressure seals are critical.

- Sewerage Systems, Industrial Water Lines, and Water Mains: Provide leak-proof connections in critical infrastructure.

- Heating, Ventilating, and Air-Conditioning (HVAC) Equipment: Used in high-pressure systems for secure pipe fittings.

- Food Processing Industry: Helps maintain hygiene and pressure control in processing plants.

- Paper & Pulp Industry: Utilized in industrial pipelines to withstand harsh chemicals and pressures.

Types of Flanges

- Socket Weld Flanges

- Threaded Flanges

- Reducing Flanges

- Orifice Flanges

- Industrial Flanges

- Slip-on Flanges

- Blind Flanges

- Lap Joint Flanges

- Ring Joint Flanges

- Spectacle Flanges

Hilton Metals: Leading Supplier of Ring Joint Flanges in India

Hilton Metals is recognized as one of India’s premier suppliers of Ring Joint Flanges, distinguished for our unwavering commitment to delivering high-quality products, exceptional customer service, and advanced in-house processing capabilities. Our pursuit of excellence has made us a trusted name in the supply of Ring Joint Flanges, establishing us as a leading provider in India. As an ISO 9001:2009 certified company, Hilton Metals has been serving the industry since 2004, consistently prioritizing product reliability and performance.

We have built a solid reputation as a key manufacturer and supplier of Ring Joint Flanges in India, owing to our steadfast dedication to quality and client satisfaction.

Client Projects and Global Reach

Hilton Metals stands proudly as one of India’s most reliable Ring Joint Flange dealers, consistently receiving top-tier ratings from our global clientele. We supply Ring Joint Flanges to over 60 countries on a monthly basis, serving a wide range of industries. With a proven track record of over two decades, we have successfully dispatched more than 3,500 containers of Ring Joint Flanges worldwide. Our reputation for fast delivery, competitive pricing, and exceptional product quality has earned us a position of trust in the international market.

In India, Hilton Metals has supplied Ring Joint Flanges to various cities, solidifying our standing as a preferred and dependable supplier across the nation.

| Product supplied |

City |

| Ring Joint Flanges for Automobile Industry |

Delhi, New Delhi |

| Ring Joint Flanges supply |

Hyderabad, Telangana |

| Ring Joint Flanges supply for Water Supply System |

Banglore, Karnataka |

| Ring Joint Flanges for Chemical industry |

Surat, Gujarat |

Cities We Supply Weld Flanges